Executive Summary

Composites have been employed in space applications for decades, and their application continues to grow. Composite applications can be seen on human spaceflight vehicles, satellites and payloads, and the launch vehicles used for space transportation. Composites in spacecrafts have proven to be successful and valuable when the mission requires the spacecraft to be lightweight and have environmental stability. In addition, advanced composites are majorly used in launch vehicles for a growing number of applications. For instance, solid rocket motors and pressure vessels, which are used for fuel and gas storage, are usually reinforced with advanced composites such as carbon fiber reinforced composite. Composites have become a requirement for ablative and other high-temperature components in rocket motor nozzles and re-entry heat shields.

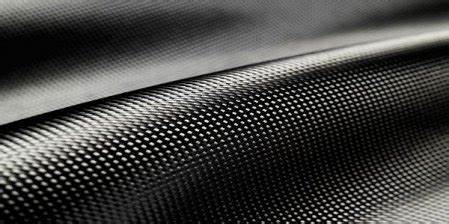

Advanced composites offer cost-effectiveness, ease of process ability, high strength to weight ratio, multi- functionality, and diverse properties in terms of thermal insulation and ablation. High modulus carbon fiber reinforced laminates are one of the majorly used for many composite spacecraft applications. In human crew capsules, composite panels are used to provide for the thermal protection system (TPS) required for vehicle re-entry. The temperature capability and low thermal expansion offer additional benefits by reducing the amount of TPS material required, which reduces the weight of the vehicle. Carbon fiber laminates are widely used on satellites and payload support structures. For instance, satellite bus structures are made using aluminum honeycomb sandwich panels with either carbon fiber or aluminum face sheets. Also, high-modulus, high-thermal conductivity carbon fiber laminates with low moisture absorption resins, typically cyanate ester, are always used for manufacturing optical benches and other spacecraft structures, which must sustain dimensional stability for accuracy. These advanced composites help in maintaining extreme dimensional stability over extreme temperature when the spacecraft is in space. Apart from this, RF reflectors and solar array substrates also use high-modulus carbon fiber laminates in order to achieve stiffness and dimensional stability.

There are several factors that contribute to the growth of the advanced space composites market. Technologies such as reusable launch vehicle systems, on-orbit manufacturing technologies, and upcoming space stations and habitats have the potential to further the use of advanced composites for space applications. The companies operating in the advanced space composites market are highly engaged in research and development initiatives and have been investing in developing new innovative technologies that would enhance space systems. The key players in the advanced space composites market include companies such as Applied Composites, ACPT Inc. (Advanced Composite Products and Technology), AdamWorks, Airborne, Cecence Limited, Cimarron Composite, CST Composites, HyPerComp Engineering, Infinite Composites Technologies, Matrix Composites, Peak Technology, RUAG Group, Stelia Aerospace North America, Hexcel Advanced Composites, and Toray Advanced Composites, among others. These companies are also working with government agencies as well as military organizations to provide them with their proven capabilities.

Additionally, there are several factors that are contributing to the significant growth of the global advanced space composites market. Some of these factors include increasing deployment of growing satellite launches and deep space activities, rising demand for radiation hardened electronics in the communication satellite segment, advancement in 3D printing technology for the space industry, and adoption of new materials to manufacture space products.

Satellite Platform Segment to Witness Fastest Growth in Global Advanced Space Composites Market

With the rise in satellite launches in the past few years and expected small satellite mega constellation in the next decade, it is anticipated that the satellite platform will register the highest growth during the forecast period (2021-2031).

Structure Component Segment to Dominate the Global Advanced Space Composites Market

The commercial end users are continuously working on developing efficient and cost-effective satellites as well as developing reusable launch vehicles. The structure component segment is expected to dominate the market during the forecast period from 2021 to 2031. The factor contributing to this growth is the increased focus of the space companies to develop reusable launch vehicles as well as small launch vehicles (SLVs).

Carbon Fiber Segment to Lead the Global Advanced Space Composites Market

The space industry has been using carbon fiber composites to manufacture satellite structures and launch vehicle structures. With the increase in satellite manufacturing due to increased launches, the carbon fiber segment is expected to lead the advanced space composites market during the forecast period 2021-2031.

North America to Dominate the Global Advanced Space Composites Market

North America is expected to dominate the global advanced space composites market during the forecast period. The factor attributing to the growth of this region is the presence of the key companies highly engaged in developing and engaged in providing advanced materials for space applications. Additionally, the continuous technology advancement by key players in the satellite industry is another factor contributing to the growth of the market. Apart from this, the region’s companies are in long term relationships with space agencies and are engaged in programs that will propel the space sector in the region.

Competitive Landscape

The competitive landscape of the advanced space composites market consists of different strategies undertaken by major players across the industry to gain market presence. Some of the strategies adopted by advanced space composite providers are contracts, agreements, new product launches, business expansions, partnerships, and collaborations. Among all the strategies adopted, contracts, agreements, partnerships, and collaborations have been the most prominent strategy adopted by the players in the advanced space composites market.

Most of the advanced space composites solution providers have numerous tie-ups with various national space agencies and commercial space players. Innovation and development have been the key factors for large- scale growth in this market. To increase their overall global footprint, the advanced space composites providers are expanding their businesses and are also entering into strategic partnerships to increase their customer base.

Global Advanced Space Composites Market: Overview

The several space programs and advancements in space research have been the primary focus of many developed and developing countries. The space activities provide the country with a broad scope of beneficial applications, which includes citizen development, mass communication, agriculture, economy, defense, scientific and medical research.

When the Apollo capsule was developed, the composites industry was still in its early stages, and the materials were not yet used widely in the space industry. The Apollo capsule used early composite technology in the form of an ablative heat shield made from Avcoat, an epoxy novolac resin with silica fibers in a fiberglass- phenolic honeycomb matrix. A fiberglass honeycomb was bonded to the primary structure, and the paste-like material was injected into each cell individually. Since the development of Apollo, advanced composites have progressed and have played a significant role in space programs with use in launch vehicles, the space shuttle, satellites, space telescopes, and the International Space Station.

Liquid resin infusion has been used in composites manufacturing for decades. It is being used to produce large aerostructures and is a serious contender for the high-rate manufacturing of single-aisle commercial aircraft. Compression molding has also been used in the past and is one of the enabling technologies for high-volume auto composites manufacturing. The technological advancement in the composites industry for creating the next generation of materials and processes does not depend on developing new materials but adapting proven technologies to serve highly dynamic and demanding applications.

Currently, the space sector has entered into a new phase wherein space exploration and on-orbit capabilities are the major focus. For instance, the U.S. is focusing on its returning to the moon by the U.S. astronauts by 2024 and has announced a 2021 budget of more than $XX billion for the National Aeronautics and Space Administration’s (NASA) human space exploration program. Additionally, NASA has current and forthcoming missions to study our solar system, from the sun to the icy moons of the outermost planets and beyond.

Apart from this, small satellites have been gaining traction owing to the significant mass reduction along with high-cost efficiency. The interest in small satellites has increased exponentially during the last few years. Over the past decade, nearly $XX billion has been invested in small satellites, of which half of the amount has been generated in the last two to three years (2018-2020). Revolution in the small satellite domain originated from the fly-learn-refly approach to the development and launch of satellites.

Business Drivers

Numerous countries have been launching small satellite constellations and deep space missions for applications such as real-time Earth observation, navigation, tracking and monitoring, and global internet coverage. There is an extensive demand for satellite constellations in the market owing to the increasing need for faster, reliable, and efficient real-time tracking and monitoring systems for cargos, ships, etc., and Earth observation (EO).

As per the Union of Concerned Scientists (UCS), more than XX satellites were launched in 2020. These small satellites were launched for commercial, government, and military applications. It is expected that large satellites may be gradually replaced with a cluster of small satellites in a single orbital location. Once the technology becomes available, small satellite constellation systems can perform better, cost less to launch, and operate equivalent to conventional satellite systems. This is expected to enhance the global advanced space composites market during the forecast period.