The Southeast Asian automobile industry is a dynamic and rapidly growing sector that encompasses various aspects of the value chain, from raw material extraction to manufacturing and distribution.

Key Components of the Southeast Asian Auto Industry Chain

1. Raw Material Supply

- Steel and Aluminum: These are crucial for manufacturing car bodies and engines. Southeast Asia has significant production capabilities in countries like Indonesia and Malaysia.

- Plastics and Rubber: Essential for tires and interiors, with Thailand being a major producer of natural rubber.

- Electronic Components: Increasingly important with the rise of electric vehicles (EVs), with Malaysia and Singapore being notable producers of semiconductors.

2. Manufacturing and Assembly

- Major Hubs: Thailand is known as the “Detroit of Asia” due to its extensive car manufacturing industry. Other significant players include Indonesia, Malaysia, and Vietnam.

- Automakers: Global brands like Toyota, Honda, and Nissan have substantial manufacturing operations in the region. Local brands are also emerging, such as Proton in Malaysia and VinFast in Vietnam.

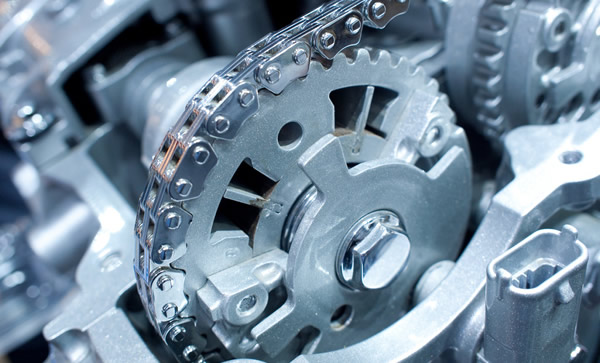

- Components and Parts Suppliers: The auto parts supplier market in Southeast Asia is robust, with a mix of local companies and multinational corporations playing crucial roles. A strong network of suppliers supports the assembly plants, providing everything from engines to electronics.

- Tier 1 Suppliers: These are large companies that supply major systems directly to OEMs (Original Equipment Manufacturers). Examples include Denso, Aisin, and Bosch, which have significant operations in Thailand, Malaysia, and Indonesia.

- Tier 2 and Tier 3 Suppliers: These companies provide smaller components and raw materials to Tier 1 suppliers. They include manufacturers of specialized parts like screws, bearings, and small electronic modules.

- Local vs. Global Suppliers: The supply chain includes both local companies and multinational corporations. Local suppliers often focus on less complex components, while global suppliers provide high-tech parts.

- Here’s an in-depth analysis of the major suppliers, their contributions, and key facts:

- Denso Corporation

- Headquarters: Japan

- Operations in Southeast Asia: Significant presence in Thailand, Malaysia, and Indonesia.

- Products: Advanced automotive technology, systems, and components, including powertrain systems, thermal systems, and electronic systems.

- Key Facts: Denso has several manufacturing plants in the region, including its largest facility outside Japan located in Thailand. The company focuses heavily on R&D and innovation, especially in areas like fuel efficiency and electric vehicles (EVs).

- Aisin Seiki Co., Ltd.

- Headquarters: Japan

- Operations in Southeast Asia: Manufacturing plants in Thailand and Indonesia.

- Products: Wide range of automotive parts including drivetrain, body, brake & chassis, engine, and information technology.

- Key Facts: Aisin is a major supplier for Toyota, with extensive operations in Thailand where it produces a variety of components. The company invests in advanced manufacturing technologies and sustainability initiatives.

- Bosch

- Headquarters: Germany

- Operations in Southeast Asia: Production facilities and R&D centers in Malaysia, Thailand, and Vietnam.

- Products: Automotive technology and services, including mobility solutions, industrial technology, and consumer goods.

- Key Facts: Bosch operates several plants and innovation centers in the region, focusing on electrification, automation, and connectivity solutions for the automotive industry.

- Continental AG

- Headquarters: Germany

- Operations in Southeast Asia: Manufacturing and R&D presence in Malaysia, Thailand, and Indonesia.

- Products: Tire technology, brake systems, powertrain and chassis components, instrumentation, infotainment solutions, and vehicle electronics.

- Key Facts: Continental has been expanding its footprint in Southeast Asia with significant investments in Thailand and Malaysia, emphasizing local R&D capabilities and sustainable production practices.

- Toyota Boshoku Corporation

- Headquarters: Japan

- Operations in Southeast Asia: Manufacturing facilities in Thailand and Malaysia.

- Products: Interior components, filtration systems, and powertrain components.

- Key Facts: As part of the Toyota Group, Toyota Boshoku has a strong presence in Southeast Asia, supplying components for Toyota vehicles produced in the region.

- Denso Corporation

You can also refer to our report: Vietnam Auto Parts Industry Research Report 2023-2032

3. Research and Development (R&D)

- Innovation Centers: Increasing investment in R&D, particularly in Malaysia and Singapore, focusing on electric vehicles, autonomous driving, and smart technologies.

- Partnerships: Collaboration with global tech firms and universities to drive innovation.

4. Sales and Distribution

- Dealership Networks: Extensive networks across urban and rural areas, with a focus on both new and used car markets.

- E-commerce: Growing importance of online platforms for car sales, especially in more developed markets like Singapore and Malaysia.

5. Aftermarket Services

- Maintenance and Repair: A robust sector with numerous service centers, both authorized and independent.

- Spare Parts: A significant market for spare parts, driven by both domestic production and imports.

6. Policy and Regulation

- Government Incentives: Various governments offer incentives to attract foreign investment and promote local manufacturing. For example, Thailand’s eco-car program and Malaysia’s national car policy.

- Environmental Regulations: Increasing emphasis on emissions standards and promoting EVs to address pollution concerns.

7. Trends and Challenges

- Shift Towards Electric Vehicles (EVs): Growing interest and investment in EVs, with countries like Thailand and Indonesia aiming to become EV production hubs. Many suppliers are adapting their product lines to cater to the growing electric vehicle market, investing in R&D for battery technology, electric powertrains, and related systems.

- Supply Chain Disruptions: Challenges from global events such as the COVID-19 pandemic and geopolitical tensions affecting supply chains.

- Market Demand: Rising middle-class incomes driving demand for automobiles, but also facing competition from other modes of transportation like motorcycles and public transit.

- Digitalization and Industry 4.0: Suppliers are increasingly adopting digital technologies, such as IoT, AI, and robotics, to enhance manufacturing efficiency, quality, and traceability.

- Sustainability Initiatives: There is a strong focus on reducing the environmental impact of manufacturing processes, with investments in renewable energy, recycling, and green technologies.

The Southeast Asian automobile industry is characterized by a diverse and complex value chain with strong manufacturing capabilities, a growing focus on innovation, and significant government support. While there are challenges such as supply chain disruptions and environmental concerns, the region’s strategic importance in the global automobile market is poised to grow, especially with the increasing emphasis on electric vehicles and advanced automotive technologies.